P series – Paraffin Wax

A substance that absorbs and releases thermal energy by solidifying and melting a two-phase change at a specific defined temperature, thereby regulating the ambient temperature.

P series phase change material - paraffin wax has been widely used in power batteries, battery packs for energy storage systems and other equipment systems. The product has the following advantages :

- Balance battery ambient temperature and increase battery life

- Paraffin wax can be used as a structural strength aid when curing at room temperature

- Prevent battery propagation, thermal runaway issue and avoid battery pack explosion

Application

Power battery industry, energy storage system and other high-integrated heat storae requirements. Also widely used in large-scale energy storage equipment to adjust cell temperature and increase cell life.

Features and Benefits

- No supercooling effect during solidification

- able to melt consistently

- Good compatibility with conventional structural materials

- chemically stable

- Safety, no qualitative change issue

| Property | Unit | P5348 | P5651 | P6254 | P6455 | P6755 | Test Standard |

|---|---|---|---|---|---|---|---|

| Melting Point | ℉ | 124 ~129 | 132 ~ 136 | 136 ~ 142 | 144 ~ 150 | 153 ~ 158 | ASTM D87 |

| Start endothermic temperature | ℃ | 48 | 51.2 | 54.02 | 55.61 | 55.04 | - |

| End endothermic temperature | ℃ | 56 | 57.5 | 64.22 | 67.5 | 71.11 | - |

| Oil Content | wt% | Max. 1.5 | Max. 0.5 | Max. 0.5 | Max. 0.5 | Max. 1.0 | ASTM D721 |

| Needle Penetration | 1/10mm @77℉ | Max. 40 | 11.0 ~ 17.0 | 12.0 ~ 17.0 | 14.0 ~ 18.0 | 15.0 ~ 20.0 | ASTM D1321 |

| Kinematic Viscosity | cSt. @212 ℉ | 3.7 ~ 4.2 | 3.4 ~ 4.0 | 4.2 ~ 4.9 | 4.8 ~ 5.6 | 6.0 ~ 7.5 | ASTM D445 |

| Saybolt Color | +25 ~ +30 | +26 ~ +30 | +26 ~ +30 | +26 ~ +30 | Max. +10 | ASTM D156 | |

| Flash Point | ℃ | Min. 210 | Min. 220 | Min. 230 | Min. 240 | Min. 240 | ASTM D92 |

| Volume Expansion rate | % | 12 | 12 | 11.8 | 11.6 | 11.6 | - |

| For full specifications, please contact PROMI. This physical property table is a typical test value and is for reference only, not as a formal quality assurance commitment. |

|||||||

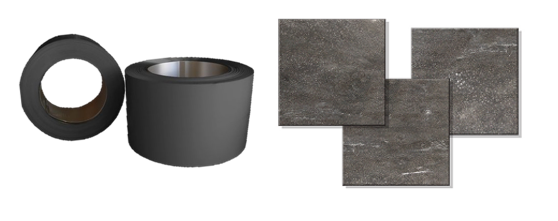

PK902 series

Thin-film phase change material. Ultra-thin thickness, takes up only little space, and is suitable for use in portable devices with small space.

Application

PK902 series phase change materials are widely used in:

- Consumer electronics such as laptops, mobile phones, and other electronic products with high integrated heat dissipation requirements

- Memory modules, power modules, power semiconductor devices

- Solid State Relays, Cache Memory Chips

Features and Benefits

- Endothermic enthalpy value of phase change material: ≥140 J/g

- Thermal conductivity: 2.0W/m.K

- Easy to cut, low density

- Large specific heat capacity

| PROPERTY | PK902-H37 | PK902-H45 | PK902-H53 | PK902-H58-100 | Test Standard |

|---|---|---|---|---|---|

| Color | BK | BK | BK | BK | Visual |

| Thermal Conductivity | 1.5 ± 0.3 W / MK | 1.5 ± 0.3 W / MK | 1.5 ± 0.3 W / MK | 1.5 ± 0.3 W / MK | ASTM D5470 |

| Flammability rating | HB | HB | HB | HB | UL-94 |

| Endothermic enthalpy | 160±10% J/g | ≥140 J/g | ≥140 J/g | ≥160 J/g | ASTM D3418-15 |

| Specific heat capacity | 2.1 J/(g°C) | 2.1 J/(g°C) | 2.1 J/(g°C) | 2.1 J/(g°C) | ASTM D3418-15 |

| Specific Gravity | 1.0±0.2 g /cm3 | 1.0±0.2 g /cm3 | 1.0±0.2 g /cm3 | 1.0±0.2 g /cm3 | ASTM D792 |

| Volume resistance | -40~100 ℃ | -40~100 ℃ | -40~100 ℃ | -40~90 ℃ | EM344 |

| Adhesive strengt | ≥108 Ohm-cm | ≥108 Ωhm-cm | ≥108 Ωhm-cm | ≥108 Ωhm-cm | ASTM D257 |

| Phase transition temperatur | 37±1 ℃ | 43~48 ℃ | 50~56 ℃ | 58 ℃ | ASTM D3418-15 |

| Breakdown Voltage | ≥1500 (AC) V | ≥1500 (AC) V | ≥1500 (AC) V | ≥1500 (AC) V | ASTM D149 |

| For full specifications, please contact PROMI. This physical property table is a typical test value and is for reference only, not as a formal quality assurance commitment. |

|||||

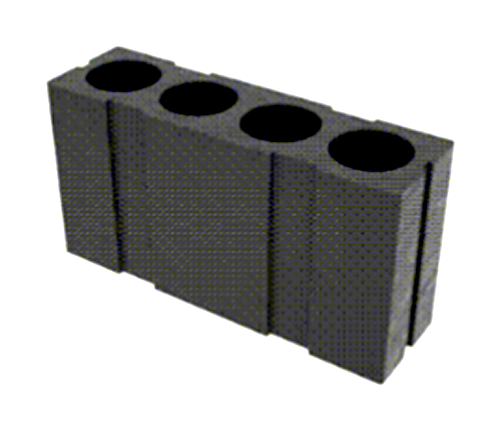

PK904 series

Application

PK904 series phase change materials, phase change cooling materials are widely used in:

- Products with high integrated heat dissipation requirements such as batteries, hand tools, and home appliance industries.

- Memory modules, power modules, power semiconductor devices

Features and Benefits

- Endothermic enthalpy value of phase change material: ≥80 J/g

- Thermal conductivity of phase change material: 0.6W/m.K

- Large specific heat capacity

- Easy to cut, low density

| PROPERTY | PK904 | Unit | Test Conditions | Standard |

|---|---|---|---|---|

| Color | Black | / | 25℃, 70RH | Visual |

| Specific Gravity | 1.3 | g/cm3 | 25℃, 70RH | ASTM D792 |

| Thermal Conductivity | 0.6 ± 0.3 | W/m.k | Conductivity Y | ASTM D5470 |

| Endothermic enthalpy | 50~100 (optional) | J/g | DSC (25℃, 70RH) | / |

| Specific heat capacity | 2.1 | J/(g℃) | DSC (25℃, 70RH) | / |

| Tensile Strength | ≧ 0.8 | MPa | 5mm/min | ASTM D638 |

| Thickness | ≧ 1.2 (Thinnest area) | mm | 25℃, 70RH | ASTM D374 |

| Hardness | 50 | Shore C | 25℃, 70RH | ASTM D2240 |

| Flame resistance | HB class | / | 2mm | UL-94 |

| Resistivity | ≧ 108 | Ω-cm | / | ASTM D257 |

| Breakdown Voltage | 300 ~ 420 (adjustable) | KV | 2mm | ASTM D149 |

| Operating Temp. | -40 ~ 120 | ℃ | / | EN344 |

| For full specifications, please contact PROMI. This physical property table is a typical test value and is for reference only, not as a formal quality assurance commitment. |

||||

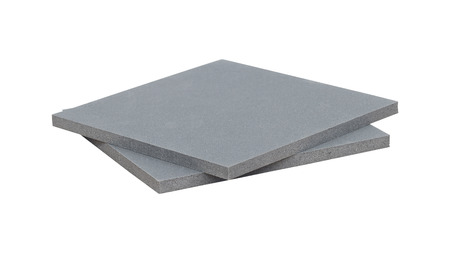

PK905 series

Application

PK905 polymer phase change energy storage material is used in the field of BMS and consumer electronic products. The phase change material delays the temperature rise by storing thermal energy and solves the issue of thermal management. This product can be directly molded and can be used as structural strength.

Features and Benefits

- Plastic strength and high endothermic enthalpy

- Excellent insulation and dielectric strength

- Large-scale production and stable quality

- Free structure design, multi-shape molding, and roll film production

| PROPERTY | PK905 | Unit | Test Conditions | Standard |

|---|---|---|---|---|

| Color | White | / | 25℃, 70RH | Visual |

| Specific Gravity | 1.2 ± 0.3 | g/cm3 | 25℃, 70RH | ASTM D792 |

| Thermal Conductivity | 0.4 ± 0.2 | W/m.k | Conductivity Y | ASTM D5470 |

| Phase Change Temperature | 37/42/46/53 | ℃ | / | / |

| Endothermic enthalpy | ≧150 | J/g | DSC (25℃, 70RH) | / |

| Specific heat capacity | 1.9 | J/(g℃) | DSC (25℃, 70RH) | / |

| Tensile Strength | 10 | MPa | 5mm/min | ASTM D638 |

| Tensile Elongation | 15 | % | 5mm/min | ASTM D638 |

| Thickness | 0.05 – 1.0 | mm | 25℃, 70RH | ASTM D2196 |

| Flame resistance | HB class | / | 1.6mm | UL-94 |

| Resistivity | ≧ 108 | Ω-cm | / | ASTM D257 |

| Breakdown Voltage | > 5 | KV | 50Hz (0.5mm) | ASTM D149 |

| Thermal Shock | 500 | cycle | -40 ~ 85 ℃, 30min/phase | / |

| Operating Temp. | -40 ~ 90 | ℃ | / | EN344 |

| For full specifications, please contact PROMI. This physical property table is a typical test value and is for reference only, not as a formal quality assurance commitment. |

||||